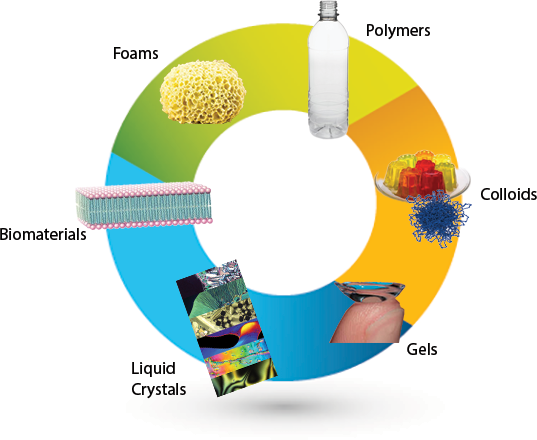

Soft matter or soft materials is a sub-field of “condensed matter” referring to a variety of materials that can be easily deformed or structurally altered by thermal fluctuations or nominal external stress. Soft materials include colloids, polymers, foams, gels, liquid crystals, and many biomaterials. They exhibit many useful and appealing properties which account for their ubiquity in everyday life, finding use in a diverse range of applications in industry including food, medical, automotive, construction, transportation, electronics, and manufacturing.

Soft matter has been studied for many years by chemists, chemical engineers, and biologist. One of the important characteristics of soft matter is their physical structures in the mesoscopic scale. It is the properties and interactions of these structures that determine the overall behavior of the material. Unlike “hard materials” such as metals, ceramics, or glass, soft material properties can be markedly affected as a result of small changes in temperature, applied force, time, and environment. For this reason, a thorough understanding of soft matter properties is essential to predicting material behavior. Fortunately, there are many characterization tools and techniques commercially available to researchers such as molecular weight determination, molecular and structural characterization by spectroscopic techniques, morphology and structural characterization by microscopy and diffraction, thermal analysis, mechanical testing, and rheology that can provide insight to the property-behavior relationships of soft materials.

Soft Matter Characterization in the SM Core Lab

Visit the INSTRUMENTS webpage for information on instrument specifications and features.

MALDI-ToF/TOF MASS Spectrometry:

The Bruker UltrafleXtreme III MALDI-ToF/ToF is a highly sensitive mass analyzer that can analyze a broad range of molecules with molecular weights of 500 to 40K daltons (high resolution reflectron mode) and as high as 600K daltons (linear mode). The technique involves the irradiation of co-crystallized sample and matrix material to form positive or negative species with mass(es) of [M + H]+ and [M – H]-, respectively, through a “soft ionization” mechanism involving a proton transfer from the matrix to the sample or deprotonation of the sample by a basic matrix.

Gel Permeation Chromatography (GPC) has been a standard for molecular weight determination of synthetic polymers for decades, but the technique has some notable limitations or challenges. MALDI-ToF has emerged as a very powerful technique that not only address most of the limitations of GPC, but also offer superior sensitivity, mass accuracy, mass resolution, solvent compatibility, and linear analysis mass range. The table below shows a comparison of the two methods for molecular weight determination of soft matter.

Visit SM Core Application Note #MS1 for additional information.

Thermal Analysis:

The Soft Matter Characterization lab has two thermoanalytical tools, the TA Instruments Differential Scanning Calorimeter (DSC) DSC250 and the TA Instruments Thermogravimetric Analyzer (TGA) TGA5500. DSC can provide accurate measurement of temperature and magnitude of phase transitions and heat capacities and allows the determination of sample impurity based on the Van’t Hoff law of melting point depression of eutectic systems. The DSC250 is a highly sensitive instrument that enable the detection of weak phase transitions and is able to separate overlapping thermal transitions that may be present in multi-component or complex samples using the modulated DSC (mDSC) feature . The TGA is a high precision, sensitive, and reliable weight balance that helps understand a material’s mass change over time and temperature and calculates weight loss due to chemicals, material breakdown, ash content, carbon black, and moisture. It can also be used to detect interactions between substances, active compounds, and packaging materials in controlled environments.

Rheometry:

The TA Instruments HR30 is a hybrid Dynamic Mechanical Analyzer (DMA) and Rheometer. Rheometry studies the flow and deformation of viscoelastic materials and the interrelation between force (applied stress), deformation, and time. The HR30 is a high-precision rheometer that can be used for viscosity and modulus measurements for characterizing non-Newtonian behaviors like shear thinning, thixotropy, and yield stress of complex fluids (emulsions, suspensions, paints, inks, coatings, slurries) and measuring material viscoelasticity (Storage Modulus, Loss Modulus, Tan Delta). The EVA accessory can be used for extensional viscosity measurement of solid samples. There are many commercially available accessories and geometries for the HR30 through TA Instruments and each provides specific measurements for a wide range of applications. Below is a list of rheology accessories and geometries available for customer use in the SM Core Lab.

- Environmental Test Chamber (ETC)

- ETC Parallel Plates

- Advance Peltier System (APS)

- Extensional Viscosity Accessory (EVA)/Sentmanat Extension Rheometer Universal Testing Assembly (SER3)

- UV Curing Accessory

- Peltier Solvent Trap and Evaporation Blocker

- Peltier Immersion Cup

- Plates and Cones (40mm/1Deg cone, 40mm plate, 40mm APS plate, 25mm parallel plate, 20mm sandblasted plate, 20mm sandblasted APS plate, 8mm plate, 8mm stepped plate)

Mechanical testing:

The TA Instruments HR30 is also capable of linear dynamic mechanical testing (DMA) of soft matter. DMA is used to characterize a material’s properties as a function of temperature, applied stress, time, frequency, and environment or a combination of these parameters. The HR30 has a patented axial DMA capability that permit amplitude-controlled oscillatory deformation in the axial direction that provides a direct measure of the modulus of elasticity, or Young’s Modulus (E), when used with the torsion/tension assembly. The HR30 DMA mode can also be used for identifying a material’s transition temperatures over a wide range of temperatures using the ETC module. The EVA/SER3 assembly is an innovative accessory that was first developed by Dr. Martin Sentmanat during his work at The Goodyear Tire & Rubber Company and is now manufactured by Xpansion Instruments. It consists of two rotating drums that allow for uniform extensional deformation during measurement. Measurements such as solids tensile testing, tear testing, peel testing, and high-rate fracture testing are possible and can be used with the HR30’s environmental test chamber (ETC). Below is a list of mechanical test accessories available for customer use in the SM Core Lab. Please visit the TA Instruments website to see other accessories commercially available for the HR30.

- Environmental Test Chamber (ETC)

- Torsion Rectangle of Film/Fiber Tension Assembly

- Extensional Viscosity Accessory (EVA)/Sentmanat Extension Rheometer Universal Testing Assembly (SER3)

Universal testing machines such as the Instron 34SC-1 Universal Mechanical Tester combines electromechanical and hydraulic systems to accomplish tests such as tensile, compression, bend, peel, tear, shear, friction, puncture, fatigue, and other mechanical tests. There are a number of accessories commercially available that are especially configured to perform each test. The Instron 34SC-1 has a maximum force capacity of 1kN and vertical test space of 41 inches which is ideal for testing of viscoelastic materials. Below is a list of mechanical test accessories and load cells available for customer use in the SM Core Lab.

- 1kN load cell

- 1N load cell

- Pneumatic clamps with rubber serrated or flat jaw attachments for tensile tests